Manufacturing of Tubes

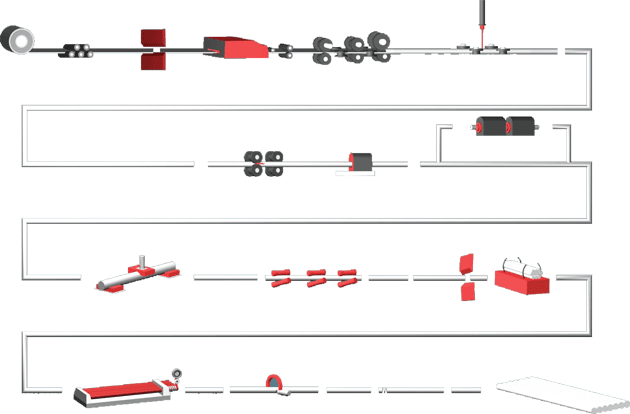

The various processes involved in the manufacturing of welded tubes are:

Depending on the specification of the product aspired by the customer, mother coil of required grade and thickness is trimmed to a width corresponding to the dimensions of the section required by the customer.

2. Tube Forming and WeldingSlitted width is given as input to the tube mill where the tube forming,welding and sizing in the desired section and dimension take place.

3. Cold drawing or SizingIf the customer tolerances are too close for the internal of external dimensions of the tube, then it is passed through this step.

4. AnnealingThe heat treatment is an optional process depending on customer application of the tube. It is done in order to reduce the internal stresses incurred in the tube during the forming process.

5. StraighteningThe process is done in order to reduce the bend caused due to forming and welding process and it also reduces the minor ovality, if any in the circular tubes and pipes.

6. PicklingIt is the surface treatment done in order to remove the scale formed due to annealing or grease and oil from the tubes, externally as well as internally.

7. PolishingCustomer having different application of tube demand for surface finishes like matte or mirror. In this process, a thin layer of material is removed using various media to obtain desired finish.

8. Cutting and End FinishProducts having requirement in cut lengths undergo this process. They are further end finished or deburred.

9. Marking and PackingMarking for traceability is done and packing is done based according to the specification given by the customers.

10. DispatchManufacturing Equipments

| Name | Quantity |

|---|---|

| Slitting machine | 2 nos. |

| Tube mills | 11 nos. |

| Straightener | 3 nos. |

| Annealing Furnace | 1 no. |

| Draw Bench | 1 no. |

| Cutting machine | 1 LAZER, 2 Auto, 2 Semi Auto, 6 manual |

| Chamfer / end finish | 4 chamfer, 1 4-spindle deburing |

| Pickling Tanks | 3 nos. |

| Polishing | 4 nos. |

| Hydraulic Presses | 3 nos. |